Narrow/Medium Web Flexo printing machine

BRIFE SPECIFICATION

-

Max. unwinding diameter :1524mm

-

Max. rewinding diameter :1524mm

-

Max. paper width :1320mm

-

Max. printing width :1300mm

-

Printing repeat length :286-1100mm

-

Register Tolerance :±0.10mm

-

Plate thickness + tape thickness :1.7mm+0.38mm

-

Substrate :Paper:60-350gsm

-

Max. designed speed : 200m/min

-

Max. printing speed : 180m/min ( The speed will be impacted by but not limited to following factors:Character of Substrate、Character of ink and additives、Printing Quality Request、Flexo plate and tape)

-

Drying system: Hot air

-

Ink :Water based ink/Solvent ink

-

Layout :Operator faces to the machine, unwinder in left hand direction

-

Machine color:DongHang standard

-

Power supply and compressed air

-

Power: 380V 3PH 50HZ

-

Compressed air:0.6MPa

-

Compressed air Consumption :2 m3/min

-

Environment requirements for workshop

-

Relative humidity: 30 -80% (at 20°C).

-

Temperature: 15°C – 35°C

-

Altitude: Less than 2000 m

-

Ground pad to fix and the thickness of the floor should be no less than 20cm

SMART OPERATION

-

Job save/recall, save necessary data of job setup, make job repeat more easily,no need set and adjust again,improve time efficiency and reduce paper waste

-

If you do not follow the procedure, the machine will alarm automatically

-

On-line monitoring of the whole machine status, real-time monitoring

-

Lack of air pressure, auto alarm

-

Each printing section was specified with control panel

-

Camera based register-Camera based registration system

-

Pre-register

-

Remote control system-Long distance diagnosis

-

Maintenance reminding,automatic remind maintenance(Weekly/Monthly/Yearly)

-

Paper path roller was made of aluminum alloy, fixed in high precision bearing, processed with dynamic and static balance

-

All parts that need lubrication are equipped with lubrication holes (Lubricants provided by customers)

-

The machine has excellent surface treatment technology. All parts and covers are surface treated, such as cleaning, rust prevention and epoxy coating

ACCESSORY DETAILS

-

The electrical cabinet is directly connected to the machine, save much more space

-

All electrical controls are installed in the electrical control cabinet, the main power supply is installed in a separate control cabinet

-

All cables are installed in the piping system to reduce the interfering signals

ELECTRICAL CONTROL CABINET-SPECIAL DESIGN

Attention: If the user's local safety regulations differ from those used by the manufacturer, the user needs to provide a full set of instructions and bear the costs of machine modification. Machine modify maybe delay the delivery time.

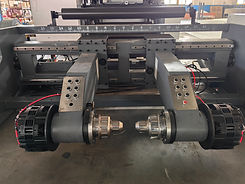

UNWIND UNIT

Max unwind diameter 1524mm Clamp type without shaft, auto lock of clamp head 3’ convert to 6’ Auto tension control system, air brake system Hydraulic roll shaft lift: used to load and unload the paper roll without the forklift. Auto stop when paper broken Paper splicing device

WEB GUIDE SYSTEM

Specified in front of the printing section Equipped with pneumatic paper-holding device to splice the paper Inspection: the edge Adopts the photoelectric sensor for web guide transmission Electronic web guide traction device. If there is any excursion in paper feeding, the system will have a constant and accurate adjustment. Adopts closed-loop control system to accurately detect the deviation and correct it.

WEB CLEAN AND ANTI-STATIC UNIT

To guarantee the cleanness of substrates First remove static, then clean the dust in vacuum and then remove static. Vacuum is formed by high pressure fan, with the collaboration of dust removal brush, it is separated by the guide groove to effectively remove the printing material dust

IN-FEED TENSION CONTROL

Use the pressure glue roller to clutch and feed paper and to ensure the tension Tension roller is driven by servo motor, the tension is controlled by servo motor to ensure the precision registration

PRINTING UNIT

Servo motors/ servo driven(Lenze/Rexroth Germany) Flower type structure achieved the dual pressure independent adjustment and locking, avoid material waste caused by frequent pressure adjustment The machine board is made of overall alloy and cast iron, which improves the stable performance and durability of the press machine For every printing section: Impression cylinder is driven separately by one servo motor, plate cylinder and anilox roller share another servo motor through gear.

INK SYSTEM

Single blade with reverse angle and ceramic coated anilox roller Easy handle without tools ANILOX ROLLERS Laser engraving ceramic anilox roller 6 pieces high precision anilox rollers The anilox roll will rotate to prevent the ink on its surface from drying and blocking holes on it

PRINTING AND SETTING

latest generation registration technology – Camera based dot model, the mark can be put anywhere Auto register for paper running direction can be controlled on both printing section and touch screen Operation direction’s registration can be realized by moving plate cylinder Plate pressure & printing pressure area adjustment will be displayed on screen

OUT-FEED TENSION CONTROL

Tension roller is driven by servo motor, the outfeed tension is controlled by servo motor to ensure the stable tension Specified with pressure glue roller to clutch and feed and to guarantee the stable tension

VISUAL REGISTER The automatic registration adopts the visual registration method independently developed by Donghang. Starting from the second color group, each color group is equipped with one camera and one industrial control computer. The registration of each color group with the base color can be corrected and adjusted in real time at the location of the color group, which can minimize the registration time and reduce paper waste. It is equivalent to installing a small image inspection device for each color group. When performing manual corrections, one can immediately see the correction results without having to wait for the pattern to reach the final inspection point, which significantly saves paper. The registration mark only requires a small dot of 1.5mm. It can be placed in the blank area of the pattern or within the shock-absorbing strip, without occupying any extra space. This significantly reduces the waste of paper edges.

IMAGE INSPECTION SYSTEM Image inspecting camera can take pictures synchronously for the printing materials Preset the inspecting position horizontally and vertically It can magnify and observe the image with a fixed position to guarantee the printing quality. High-definition resolution camera High-definition color image monitor-17” LCD monitor One high speed paparazzi flashing light Product can be magnified, and the dot can be seen clearly

PLATE MOUNTING MACHINE It has a screen including the bilateral symmetrical split-screen display It is used for the plate mounting to realize the purpose of multi-color overprinting One set image segmentation device

DRYING SYSTEM Each of the printing units is equipped separately and adopts the high-power IR light tube I.R short-wave heating and drying system and temperature is adjustable Warm air and natural air-drying system including exhaust fan and blower with adjustable volume Equipped with hot air fan to make sure the drying quality Collect the waste gas and release it through the exhaust fan IR power can be controlled separately and automatically according to the printing speed Single printing section temperature control is available, better adapt to different printing materials and reduce the energy consumption of the whole machine

REWIND UNIT Surface driven winding type Winding is controlled by motor, Independent motor drive, controlled by servo drive, constant tension control. Just set the tension value to control the paper tension. Automatic control, no manual intervention required. Dance roller, air cylinder and sensor cooperate to control the tension Rewinding unit diameter is 1524mm Pneumatic air shaft 3″ & 6” Hydraulic roll shaft lift: mainly used to load and unload the paper roll without the forklift. When the paper is broken or cracked, the machine will stop automatically Auto stop when paper broken One set paper impress roller Winding meter counting pre-set, when the meter reaches the set value, auto alarm

DOCUMENTATION Full sets of description, Includes installation operations and routine maintenance, electrical, pneumatic, and hydraulic diagrams. User must strictly follow the contents of these documents. The manufacturer is not responsible for any results If the user does not operate the device correctly according to the instructions. The user should notify the manufacturer immediately when the machine is abnormal, otherwise the user will bear the results by himself.

TWO YEARS WARRANTY

This warranty covers those defective parts which have been damaged under ordinary working conditions and by properly using the equipment; it does not cover damages deriving from an improper use of the equipment, a non-compliant use to the purpose of the machine and/or a carelessness of normal and required maintenance.

INSTALLATION AND TRAINING

Dong Hang provide 1 engineer to customer's side for installation (US$150 per day per person, customer supply the accommodation (food and hotel) and round way flight tickets and local transportation costs, quarantine and medical test cost in client’s country. Installation and training may cost 15 to 20 days.)

REMARK

DONGHANG company is qualified to make the necessary design changes without affecting the performance of the machine